Customised storage protects your profits

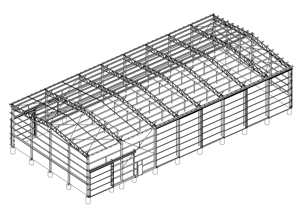

We offer experience, project efficiency and cost-effective grain and fertiliser storage solutions. We know each storage requirements is totally unique, needs to be a carefully considered design that's functional and meets your storage needs.

The space

Whether it’s grain, fertiliser, minerals or cotton, we work closely with you to understand your needs, so we can deliver a solution that strikes the right balance of light, ventilation, machinery access and protection from dust, weather and pests.

We carefully consider load bearing walls and angles of repose to ensure we correctly accommodate the input and output of your product. Our experienced consultants, design team and steel fabricators are based in-house, which allows us to collaborate on every step of your project, resulting in a smooth process and cost-effective bulk storage shed.

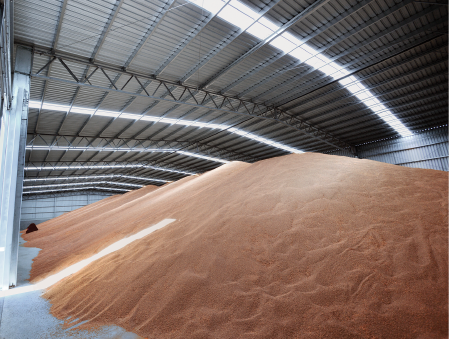

Store and ignore

Internal cladding is optimal for grain and fertiliser storage so that there are no horizontal surfaces for the product to collect on. When deciding on the best option for you, it is important to identify the bulk density (m3) of the material going into the shed to ensure the shed is fit for purpose

Internal cladding with concrete dado

This option is robust and more compatible when using heavy machinery within the shed. Typically it comprises of a concrete panel up to a specific height, designed to take the weight of grain/fertilisers and then internal cladding for the rest of the shed. Concrete dado is normally integrated with the concrete slab engineered by CSB and installed by a third party.

Internal metal cladding

The metal cladding is used as the retainer with extra supports/strengthening, up to a specified height, to cope with the weight of the grain or fertiliser. This option is more economical and able to be constructed without a concrete slab.

We do things differently

Our flexibility, experience and know-how are unrivalled in this industry, which is why nearly three quarters of our total business comes from referrals or reorders. There’s a reason why so many businesses trust us to get the job done right, and why you should trust us too.

Our hot-dipped galvanised Australian steel is a game changer in this industry - built to last for more than 50 years in most rural environments. This means you can get on with the business that matters without having to worry about your sheds or your assets.

"Central Steel Build did a good job. When we approached them with some concepts we were able to work through the different alternatives and come up with a design that was going to work for us, so that was appreciated. The drafting process flowed well and then we were put through a number of processes and teams in the business as we progressed towards construction. We’ve had a number of sheds that we’ve put up in Queensland and we were certainly impressed by Central Steel Build and the quality of their construction materials. The columns are great – you can see that there’s some proper structure. We’re very happy with the way Central Steel Build handled the process right from conceptualising through to construction and everything went smoothly. The construction was in the middle of Covid-19 which was challenging but everything happened in reasonable timeframes given the restrictions at the time.”

“This was the second shed that Central Steel Build built for us. We were pretty happy with the service we got and the shed that was delivered. They were a great mob to deal with.”

“We first found out about Central Steel Build through one of our contractors that comes here on the farm. We found it great to work with them. Any minor issues that came across soon got sorted and we were very pleased with how they helped us out.”

"Central Agricultural communicated at each level we dealt with.”

Featured bulk storage shed project case study

Having already had a great shed build experience with us, Tim Lockhart approached us again for a bulk storage shed. The shed needed to allow for easy large machinery access to deposit and load grain. We designed the building with one open side, allowing large machinery to easily access the building.

1 min read

Taking sheds to new heights: The roof-lift method

3 min read

Building permits - tips for new builds

Love what you see?

Get an obligation free quote today.