Cost To Build Dairy Barn

How much does it cost to build a dairy barn? Keeping your cows dry and protected from the elements is key to improving productivity and overall...

With a solution-focused approach, we collaborate closely with clients and consultant teams to align on scope, time frames, design objectives, and cost. We’re committed to delivering a strong return on your investment. Are you interested in our work in the commercial and industrial sectors?

Our client, a vet and sheep farmer, needed a shearing shed and yard cover designed for efficiency and innovation. Partnering with our team, he collaborated with fit-out providers to create two custom steel structures tailored to his farm’s needs. His farm is now equipped for better working conditions and long-term success.

Providing Industry-Leading Steel Building Solutions

Central Steel Build, committed to innovation, quality, and customer satisfaction, has solidified its reputation as an industry leader. We're revolutionising agricultural structures, and transforming how farmers and producers approach building solutions. If you’re interested in our work in the agricultural sector, read the article to discover how we’re transforming building solutions.

Oritech combined office and warehouse

Oritech Pty Ltd partnered with us to build a modern office and warehouse facility in Mitchell Park, Victoria. The design featured innovative L-shaped tilt panels for both function and style. Using our Pro. building approach, we delivered a durable, cost-effective, high-quality solution. Seamless collaboration ensured the project was completed on time and within budget.

Increasing production and farm efficiencies are essential in running a successful agribusiness in today's dairy industry. Effective dairy housing makes for comfortable cows, which ultimately means higher milk production. A dairy barn, custom-designed around cow comfort, site location and your facilities will significantly improve farm profitability.

Our dairy barn experts offer years of agricultural building experience to ensure your dairy barn is everything you need it to be. We offer assistance in key areas such as economical and efficient building design with a focus on airflow and cow movement to limit heat stress (one of the biggest challenges for dairy farmers in Australia) and other important aspects.

Here we have collated a list of important points to consider when planning your dairy barn in Australian conditions. To get advice specifically for your barn, contact one of our dairy barn experts here.

There are three different dairy barn systems; freestall, composting and loafing barns.

Freestall barns are fixed housing solutions designed exclusively for dairy cows. They consist of two areas; a feeding lane or ‘cow alley’ and bedding area stalls/cubicles – these are typically 1.2m wide. This design is considered a premium barn, it offers comfort, cleanliness and the opportunity to improve diet management.

Composting barns have a deep bed of wood chips or similar material so that bacterial breakdown of cow effluent creates warmth in the bedding. Correct maintenance will encourage the cow to spend more time resting which increases milk output. The barn can be built with the option of feedlanes and/or flushlanes depending on other facilities available.

Loafing barns are basic barns that provide adequate shelter to protect livestock from all weather conditions. They are often integrated with pasture so the cows can roam in and out of the barn as they please. Cows use the communal area to loaf on a soft, non-pack floor. This results in healthier, more content cows and ultimately increased milk production. Loafing barns use a soft bedding material such as straw, sawdust or woodchips that will absorb some effluent and tend to have a lower capital cost per cow than a freestall barn. However, they have higher running costs and a larger footprint in square metres per cow.

Despite which barn is right for your dairy business, each housing facticity needs to be well ventilated to achieve the following:

To find out more about the different barn types, check out our dairy barn design/build guide.

The floor area of your dairy barn can be determined by multiplying the number of cows in your herd by the amount of room per cow required plus walkways/feedlanes (if included). The average stocking rates for loose housed systems (loafing and compost) are 8-13sqm per adult cow. For freestall barns, the average stocking rate is one stall per cow.

When working out the overall building size make sure you consider passageway widths and layouts.

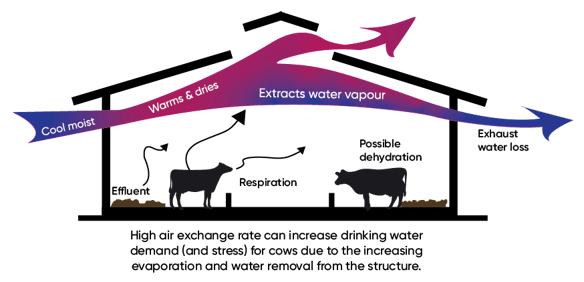

Getting the ventilation design right is very important in all three types of barns. Ventilation must be sufficient to prevent a build-up of harmful concentration of gases such as ammonia and CO2. However, cooling with air exchange is only as good as the incoming cooling air. When the temperature is high, especially in summer, cooling with air may be insufficient and artificial cooling (for example fans) may be required.

As additional moisture in loose housed systems can increase humidity, designing adequate ventilation in the building is critical. In compost barns, the pack needs to be at the correct moisture level and temperature. If either of these components are incorrect increased airflow through fans or additional bedding will be required on an ongoing basis, both of which are expensive to maintain. Having the pack at the right moisture content is essential in keeping your cows happy and healthy - if the pack is too wet, your cows have a higher risk of contracting mastitis.

Roof ridge openings are essential to allow heat and moisture to escape from the barn and must be defined prior to deciding the inlet area required in sidewalls. 75mm of opening is required for every 3m of the shed span.

The location you choose for your barn will significantly affect conditions experienced by your cows inside the structure. Any structures around your barn such as buildings, trees and silos along with the natural contour of the land will disturb airflow. This affects conditions experienced by your cows inside the structure so it's important to make sure airflow of the site works in accord with your ventilation plan in the barn.

Structures should be situated for maximum wind exposure - located at right angles to prevailing winds to allow maximum opportunity for cross ventilation. This is typically achieved by orientating the barn east to west. Positioning your build east to west also helps solar radiation which allows more sun infiltration in winter but less in summer.

The roof of your dairy barn will need to be a minimum of 4m - 5m in height, allowing for clearance of your feed wagon. The necessary eave height of your barn will depend on the density of cows you plan to have inside.

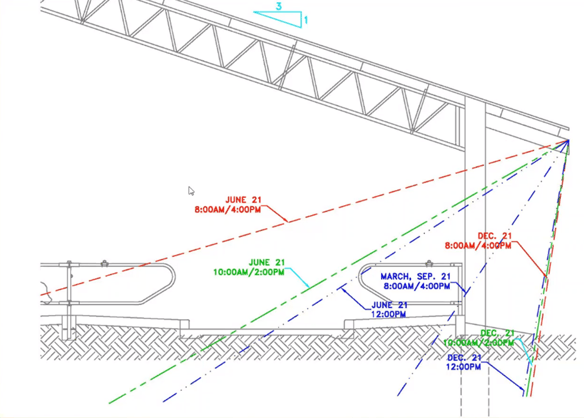

Roof overhangs can be an important feature to help reduce sunlight exposure in hotter months and to optimise sunlight in colder months, thus minimising heat stress in summer and benefiting from sunlight in winter. The most common roof overhang measurement to achieve this is 2m - 2.5m. The diagram below indicates sunlight infiltration on a barn in Australia throughout different months.

It is important to consider the position of feedlanes when designing your dairy barn as this can affect the layout of the building you choose.

When designing a loose housed barn it can be better to have a clearspan structure as internal columns channel cow flow and create internal tracks. However, if your design includes a central feedlane, internal columns correctly spaced work well and can help reduce build costs.

There are numerous options for the layout and design of freestall barns but the primary goals of the structure are:

Dealing with high temperatures is a common challenge for Australian dairy farmers. A hot roof surface produces thermal heat which is just as stressful to cows as sunlight. You can manage thermal re-radiation in your dairy barn by choosing a highly reflective outer surface (eg Zinc cladding or a light Colorbond cladding) and light coloured inner surfaces. This will help achieve stable and consistent internal temperature conditions.

The design and construction of your new dairy barn will be the catalyst for increased efficiencies and on-farm profitability. Our dedicated dairy barn experts will help customise your specific dairy building design with a range of product options for optimal results. As well, we know it's not all about the end product, we want you to enjoy (and gain from) the journey - design to handover.

If you're ready to transform your farm, let's get started. Contact us today.

Information credits

IPENZ Engineers New Zealand, Dairy Housing

Dairy Australia, Cool Cows

JGMIII, Inc. Dairy Design Engineers

How much does it cost to build a dairy barn? Keeping your cows dry and protected from the elements is key to improving productivity and overall...

How much will it cost to build a farm shed? At Central Steel Build we work hard to deliver purpose-built, high-quality agricultural spaces that are...

To help budget for your shed we’ve pulled together an approximate list of costs per m2 based on previous work completed for our clients. Prices are...