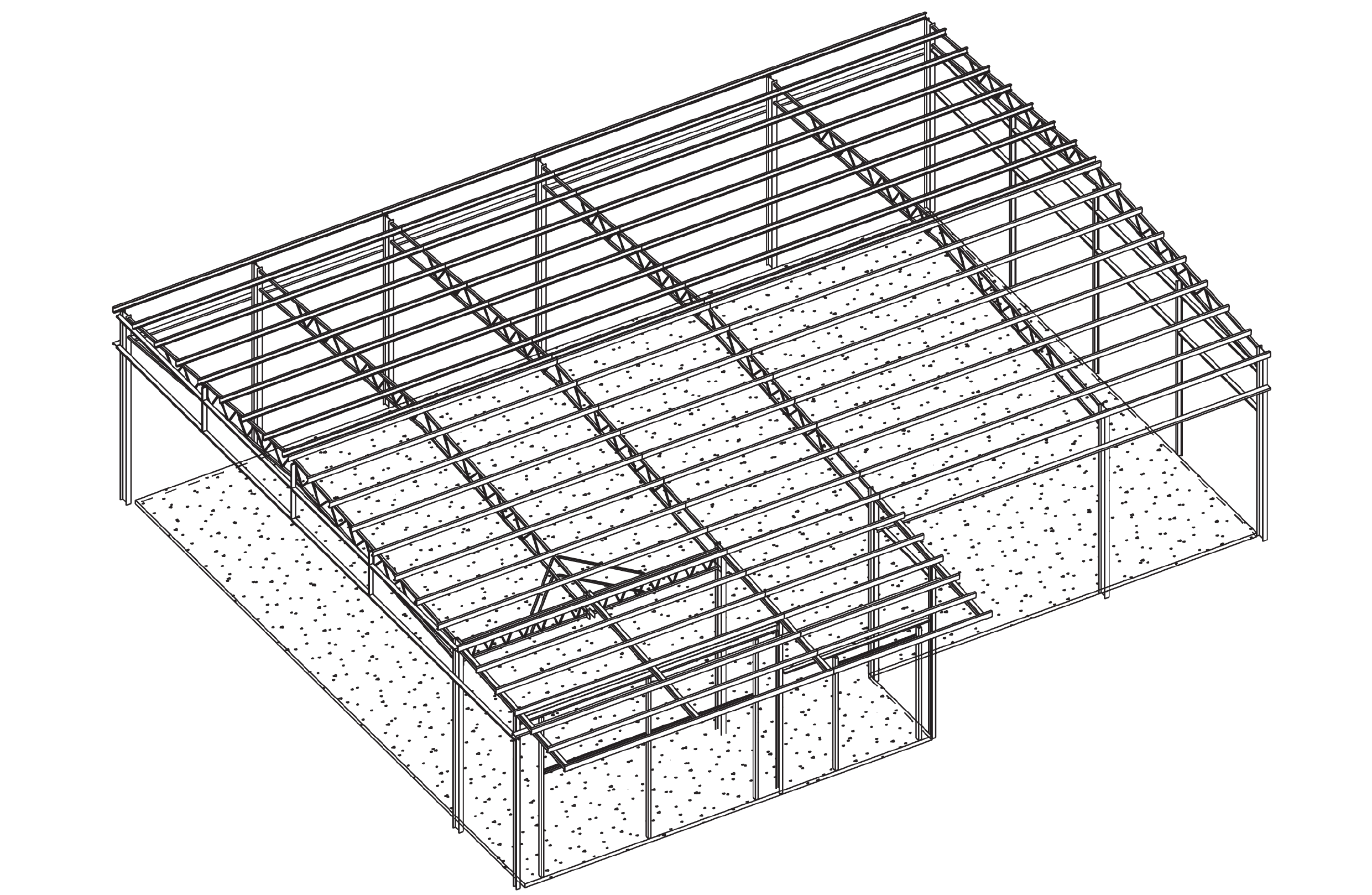

Hussey & Co horticulture shed

Project overview

Hussey & Co reached out to us to help them design and build a shed for production, storage, packing and distribution of their gourmet salad mixes. The shed needed to incorporate cool room panels and be designed to include a ramped loading dock.

Being impressed with the completed project, they contacted us for a second building that would attach to an existing cool room shed. The new structure was also designed for cool room paneling and truck loading bays.

Project value:

- $250-300K*

Building dimensions:

- 47m x 15m x 7.5m high

- 30m x 21m x 7.5m high

On-site building time:

- 15 weeks

Project collaborators:

- Rigg Drafting Pty Ltd

- Consulting geologist

- Fire engineer

Our scope and build details:

- Structural steel drawings, engineering certification and computations.

- Engineering of cool room panel loadings hanging from our structure.

- Structural concrete engineering including raft slab design for office.

- Engineering of dug in loading ramps and loading docks including specialised foundations details.

- 3D structural/shop steel drawings.

- Fabricated hot dipped galvanised steel package.

- Purlins and girts.

- Box gutter and drainage design, including between existing and new buildings.

- Cantilever canopies over truck loading bays.

Job site location:

- Somerville, Victoria

*All prices are an indication only and are subject to change at any time due to steel prices. Prices also do not include site preparation or installation costs.

Challenges and solutions

Both buildings required a lot of consideration as they were to be constructed on sites with existing infrastructure. The new sheds needed to match the surrounding buildings. We needed to engineer and design our steel frame to accommodate cool room panels and allow for exposed footings in preparation for future pit and ramp construction.

Working with specific clearance heights and site constraints, we designed some walls to be internally clad. A small cavity between the roof and the top of the cool room paneling presented a potential bird issue. We solved this by adding apron cladding around the building.

Love what you see?

Get an obligation free quote today.