Midland Pty Ltd industrial workshop

Project overview

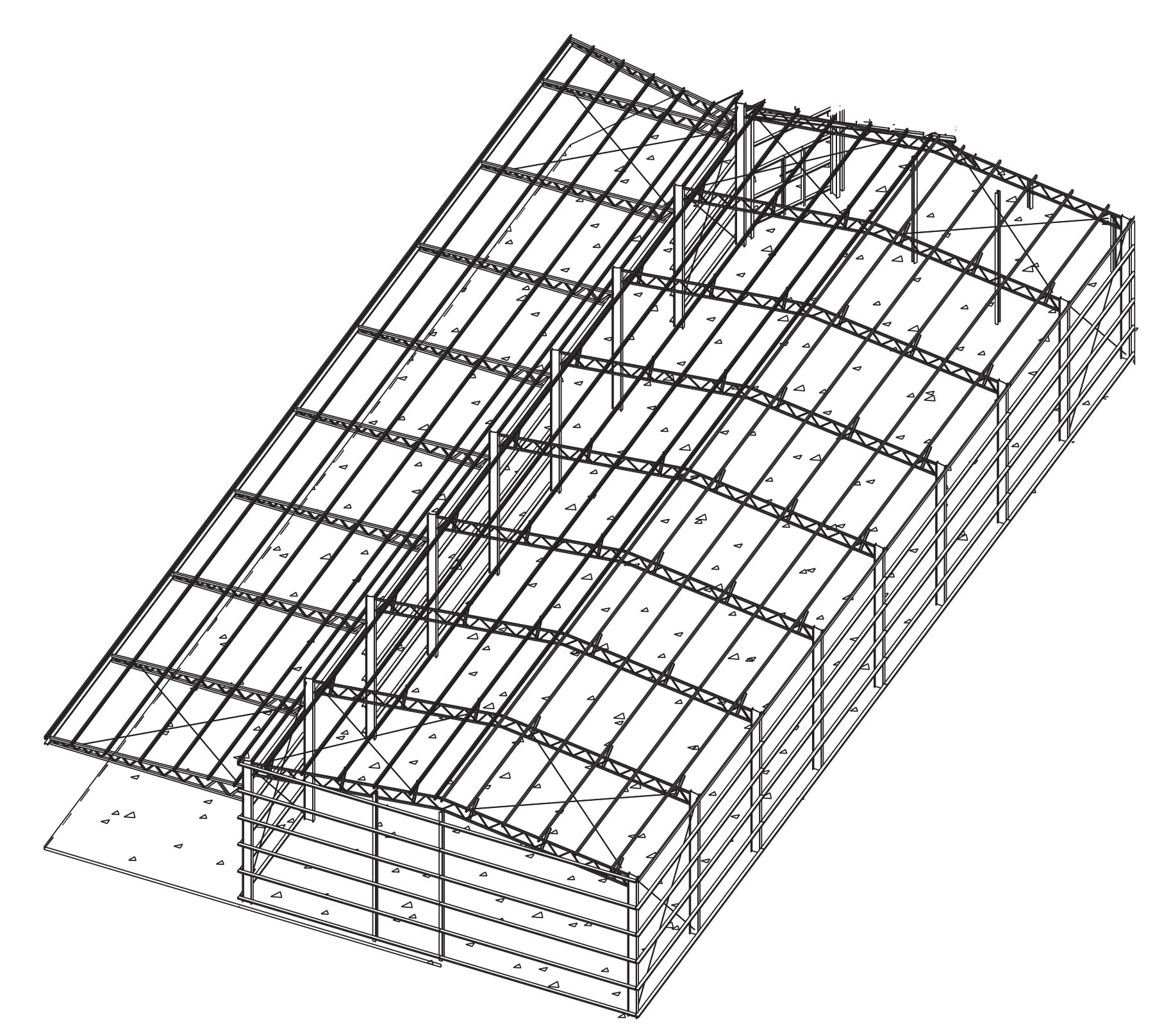

We needed to design, and value engineer the industrial workshop extension to be built on an angle between the existing building and the boundary. The shed needed to be built around the existing infrastructure on the property and have a concrete panel fire wall on the boundary.

Our steel frame was required to be engineered for gantry cranes which included crane runway beams. There was also a requirement for multiple cranes in the building, so we had to engineer for multiple cranes running in multiple directions.

- $400K

- 30m x 18m x 7.5m with a 9m wide canopy

- 7 weeks

- Laker Group

- Geotech consultant

- JDN Monocrane

- 3D structural model.

- Fabricated hot-dipped galvanised steel package.

- Purlins and girts.

- Roof and wall cladding.

- Personal access doors.

- Crane runway beams.

- Roof vents.

- Roof sisalation.

- Skylights.

- Guttering and downpipes.

- Cantilever canopy

- Kyneton, Victoria

*All prices are an indication only and are subject to change at any time due to steel prices. Prices also do not include site preparation or installation costs.

Challenges and solutions

To match the new building with the existing workshop we needed to coordinate several tricky factors including building on an angle from the existing structure and on the boundary line. Joining the buildings on an angle created a complicated roof join that required the incorporation of roof hips and valleys.

We needed to design the structure with crane runway beams for eight-tonne gantry cranes that ran down the length of the building and an additional three-tonne gantry crane running across the building.

“Central Steel Build were professional, punctual and reliable throughout the whole construction process. Their problem-solving skills in designing our extension to marry into our existing shed perfectly were outstanding. There were a lot of tricky angles in there and it all came together flawlessly.”

Love what you see?

Get an obligation free quote today.