Pipecon industrial workshop

Project overview

Having expanded over 30 years in business with more than 35 employees and still growing, Pipecon needed to upgrade its business premises. They contacted us to design and construct a custom industrial workshop facility to accommodate different aspects of the business.

The workshop was designed in three sections, a service bay, fabrication bay, and storage bay; with an incorporated wash bay added on one side.

- $500-700K*

- 72m x 30m x 7.5m

- 24 weeks

- Civil engineer

- JDN Monocrane

- Madin Lyons Associates

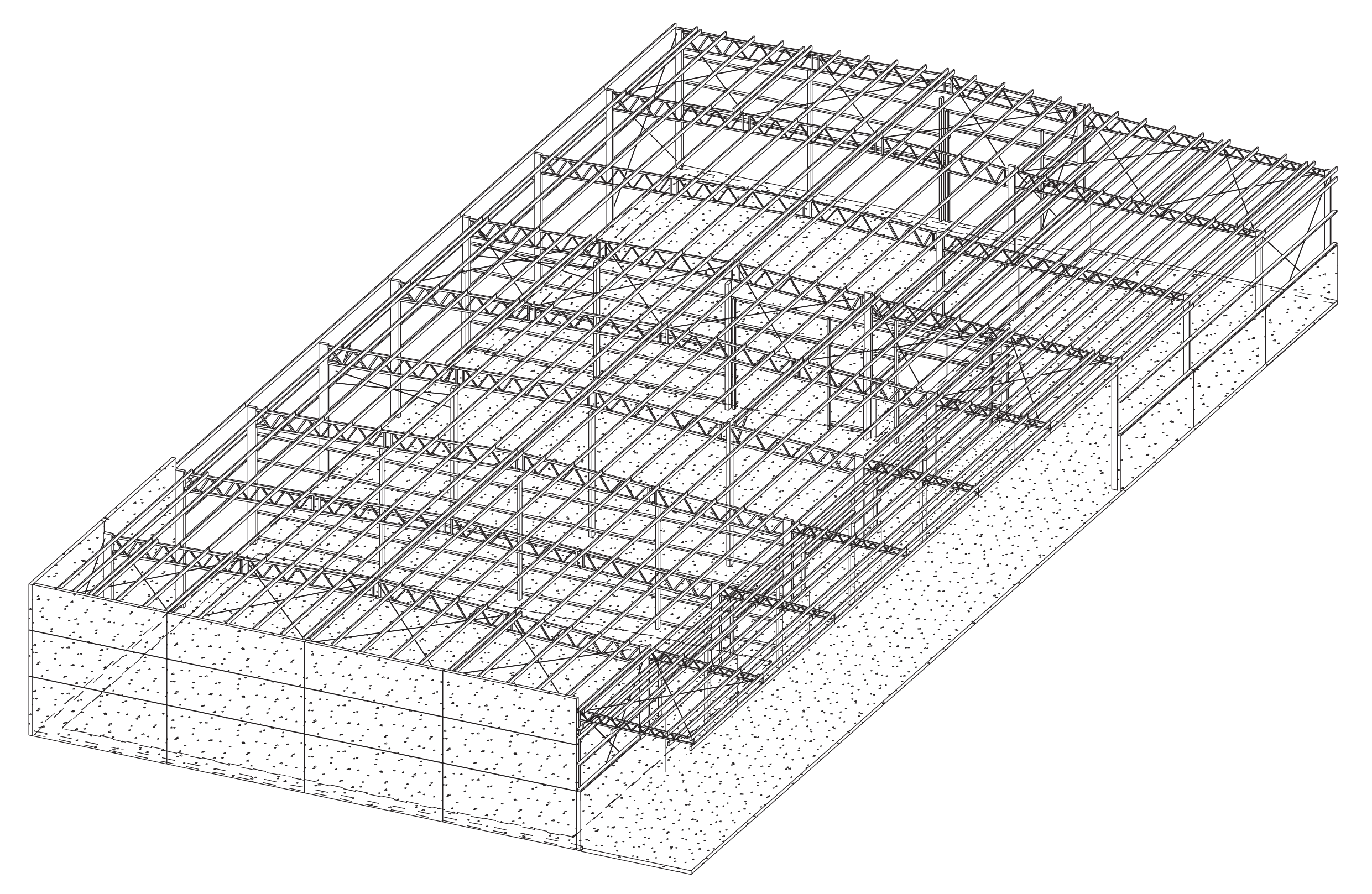

- 3D structural model.

- Fabricated hot-dipped galvanised steel package.

- Purlins and girts.

- 5kPa mezzanine.

- 72m x 6m canopy.

- Internal Colorbond partition walls.

- Colorbond soffit lining.

- Box guttering.

- Roller shutters.

- Personal access doors.

- Blanket and roof safety mesh.

- Mitchell Park, Victoria

*All prices are an indication only and are subject to change at any time due to steel prices. Prices also do not include site preparation or installation costs.

Challenges and solutions

The fabrication bay needed to have the capability to accommodate a future overhead gantry crane, hence allowance was made in the steelwork for the gantry crane including crane stubs and runway beams. Clearance heights needed to be adequate for Pipecon machinery access and a future internal gantry crane.

In addition, our client wanted the canopy on the outside to not show the web trusses, hence the soffit lining was used to create a better aesthetic look. We also designed sliding door openings to be high and wide enough for large machinery access.

“I would certainly build with Central Steel Build again and certainly recommend you. The timing, the way it was put up, everything went into place nicely, it’s very structurally sound and it’s a great-looking shed. I think it’s come up a real treat.”

Love what you see?

Get an obligation free quote today.