Steamatic warehouse

Project overview

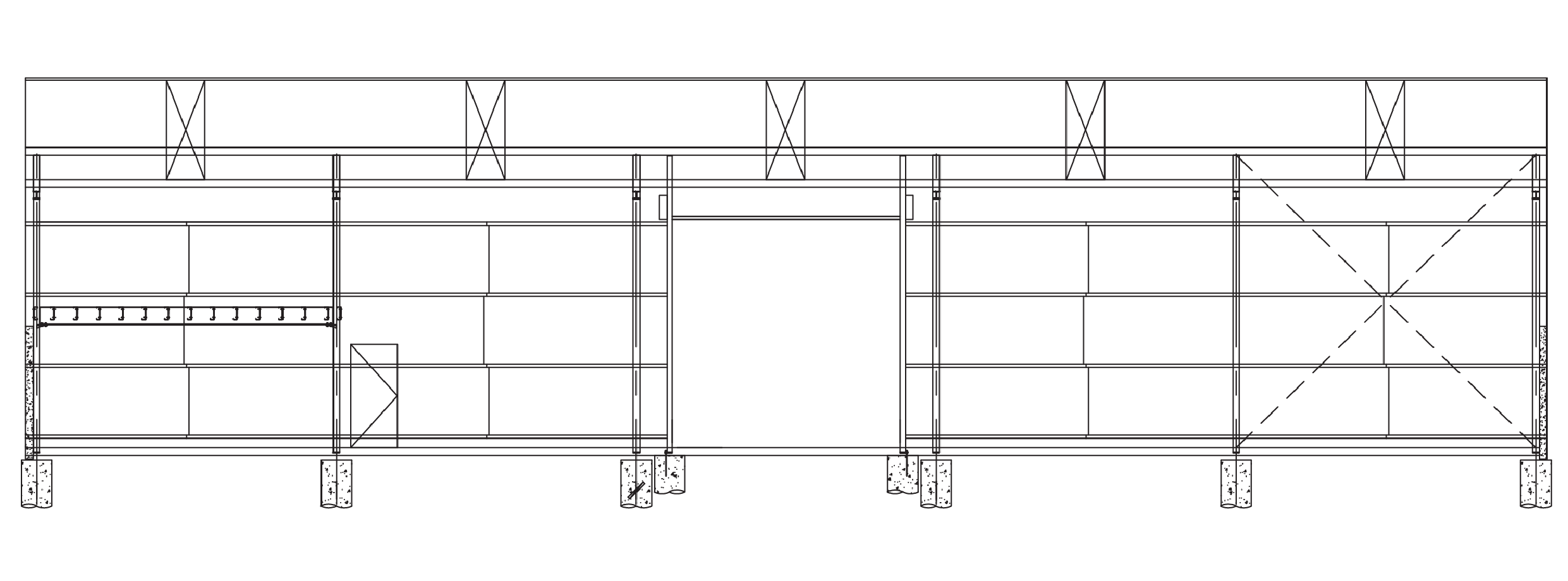

Jason Wescott Builder's client wanted the shed to utilize the maximum building footprint allowed on the property. The industrial shed needed to include ample office space and an external dispatch area to attract long-term tenants. The shed frame was required to be engineered for large entry and exit openings and to accommodate precast dado panels.

- $150-200K*

- 30m x 15m

- 3 weeks

- Bendigo Building Design

- Jason Wescott Builder

- Geotechnical Testing Services

- Structural steel drawings, engineering certification and computations.

- Structural concrete engineering including precast design.

- 3D structural/shop steel drawings.

- Fabricated hot dipped galvanised steel package.

- Purlins and girts.

- Roof and wall cladding.

- Personal access doors.

- Roller door openings.

- Sisalation and roof safety mesh.

- Cantilever canopy.

- 5 Kilopascal (kPa) mezzanine floor steelwork.

- Epsom, Victoria

*All prices are an indication only and are subject to change at any time due to steel prices. Prices also do not include site preparation or installation costs.

Challenges and solutions

Our building design team decided on a heavy-duty structural frame to support horizontal clip-on precast panels and a large 5 kPa 140 m2 mezzanine floor. This mezzanine would allow for large office space as requested by the client.

A cantilever canopy was engineered to hang off the main shed columns to allow for an unobstructed undercover loading and unloading area. For easy access into the building, large motorized roller shutters were incorporated.

To ensure an aesthetically pleasing design externally, the interface between precast panels and metal wall cladding was finished off with a seamless lip flashing.

Love what you see?

Get an obligation free quote today.